CAPACITY ANALYSIS FOR STRATEGIC GROWTH

Understanding and optimizing your capacity is essential for meeting demand and planning for future growth. Our capacity analysis services include:

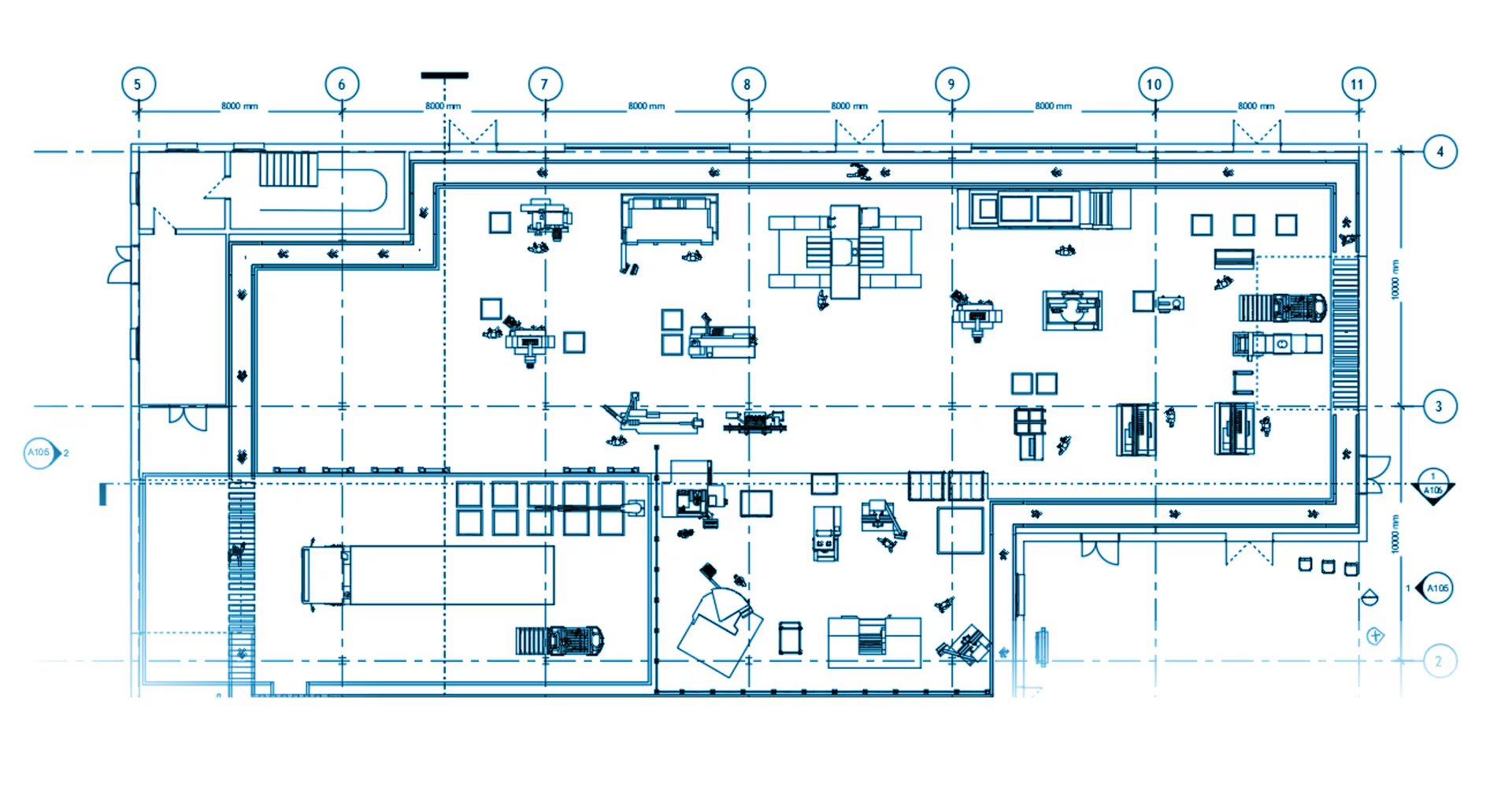

Current Capacity Assessment: Evaluating your existing production capabilities and identifying constraints.

Future Demand Forecasting: Predicting future capacity needs based on market trends and business projections.

Capacity Planning: Developing strategies to enhance capacity through equipment upgrades, process improvements, and workforce optimization.

Risk Mitigation: Identifying potential bottlenecks and implementing contingency plans to ensure consistent production levels.