WHAT ARE TIME STANDARDS?

Time standards in production and manufacturing serve as crucial benchmarks for measuring productivity and efficiency.

They enable companies to establish realistic goals, accurately estimate production costs, and ensure optimal resource allocation.

By providing a standardized framework, these methods facilitate continuous improvement efforts and help organizations streamline operations for maximum profitability.

TYPES OF STANDARDS

We can categorize Standards under the following umbrellas:

DIFFICULTY OF IMPLEMENTATION

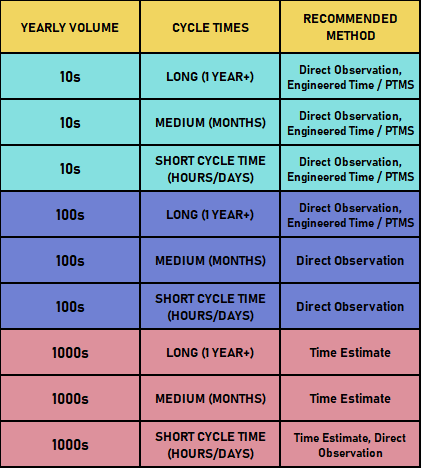

WHICH TIME STANDARD METHOD SHOULD I USE?

This is highly dependent on various factors including –

– Cycle Time of Products

– Number of Engineers in Business

– Yearly Volume of Product

Volume Translates to Build Variability, if we don’t build something a lot it is likely to be more variable and more difficult to build.

Less Volume means Higher Variability but Less Historical Data, which means a heavier leaning on Direct Observation/Engineered Time

More Volume means Less Variability, can place more emphasis on Time Estimates and use previous build data to predict future builds

PRO vs CON

Overview of Benefits and Cons of Time Standard Type