TIME ESTIMATE INTRODUCTION

Welcome to our exploration of time estimates time standards in manufacturing.

Here, we unpack the art and science of project time estimation, offering invaluable insights for professionals seeking to set realistic timelines and optimize resource allocation. Dive into proven methodologies and best practices that empower you to forecast time durations with confidence and precision. Whether you’re a seasoned project manager or a novice industrial engineer, discover the tools and strategies needed to elevate your time estimation game and achieve project success.

When do we use Time Estimates as a method for our Time Standard?

Very Limited Engineer Resources, less time consuming than the other time standard methods, but at the cost of accuracy and precision.

Quick Results, ideal when tasks are simple in nature, as they allow for easy time estimates.

Low Process Variability, time estimates typically use the average values, with low process variability our averages will be closer aligned to reality.

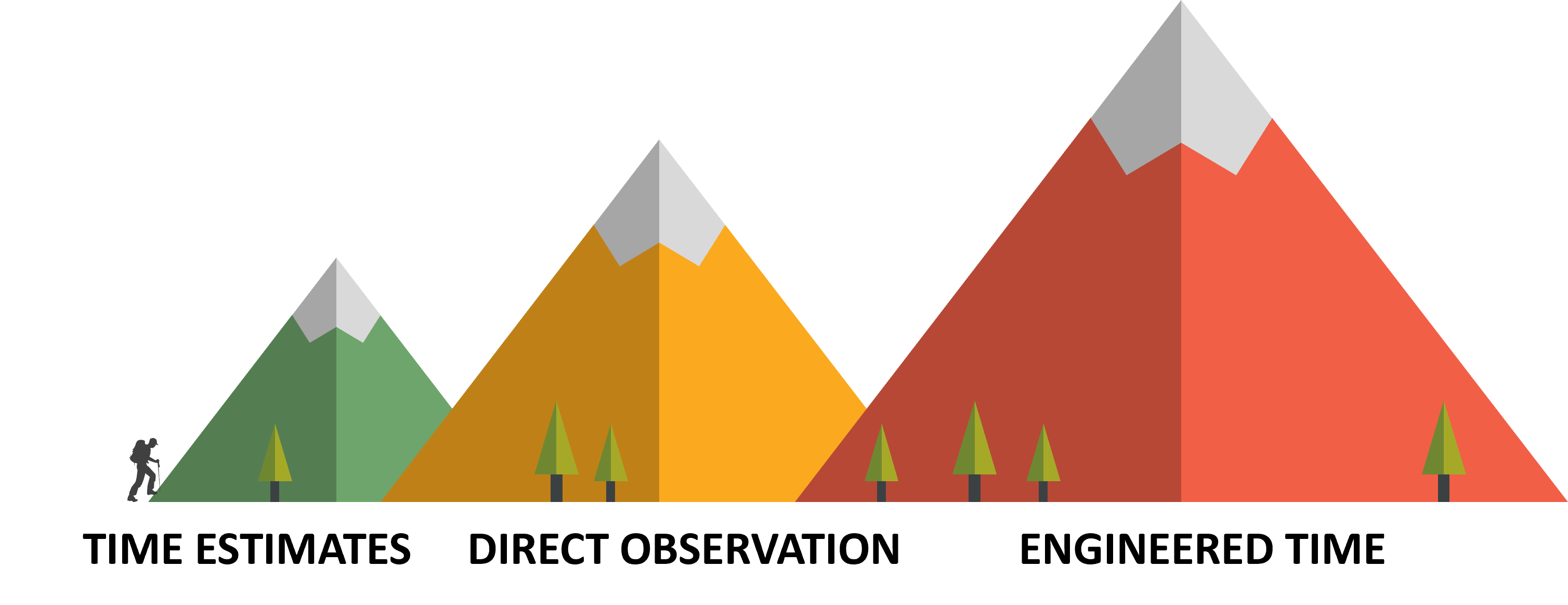

Effort of Implementation

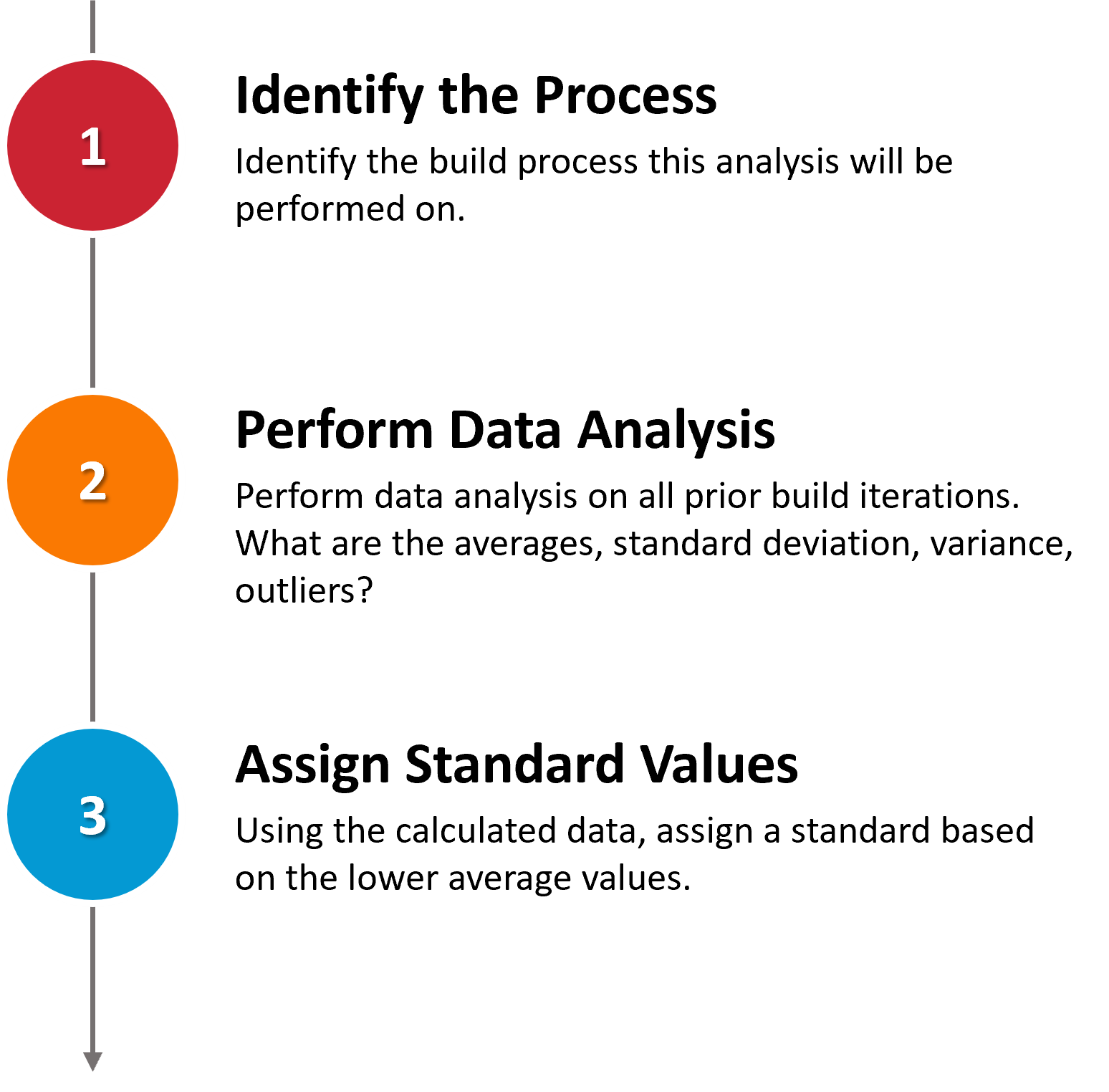

HOW TO PERFORM A TIME ESTIMATED TIME STUDY?

What are the Time Estimate systems or methods?

Click Each Type Above to Learn More

LEARN ABOUT THE OTHER TIME STANDARD METHODS BELOW:

PRO vs CON

Overview of Benefits and Cons of Time Standard Type