ENGINEERED TIME INTRODUCTION

Welcome to our exploration of engineered time standards in manufacturing, often referred to as Predetermined Motion-Time Systems (PMTS).

Engineered time standards are meticulously crafted benchmarks that capture high detail of productivity within industrial settings. By methodically analyzing processes and leveraging advanced techniques, engineered time standards serve as a cornerstone for enhancing detailed operational performance and driving success in the manufacturing sector.

When do we use Engineered Time as a method for our Time Standard?

High Process Variability, there is no defined data for the process, build times have high variability and tasks are not documented.

Process has Limited Task Documentation and no best practices in place to perform the work or is a New Process

Performing detailed process improvement as individual motions and wastes are analyzed in the system.

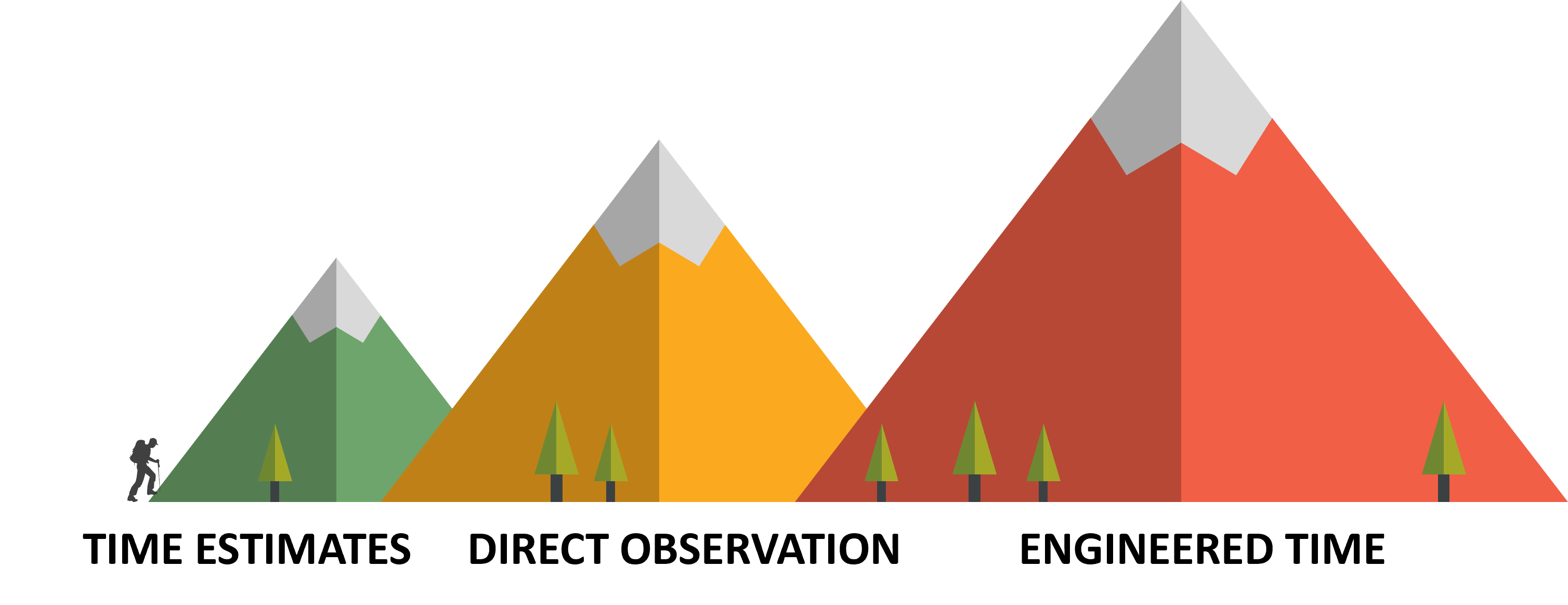

Effort of Implementation

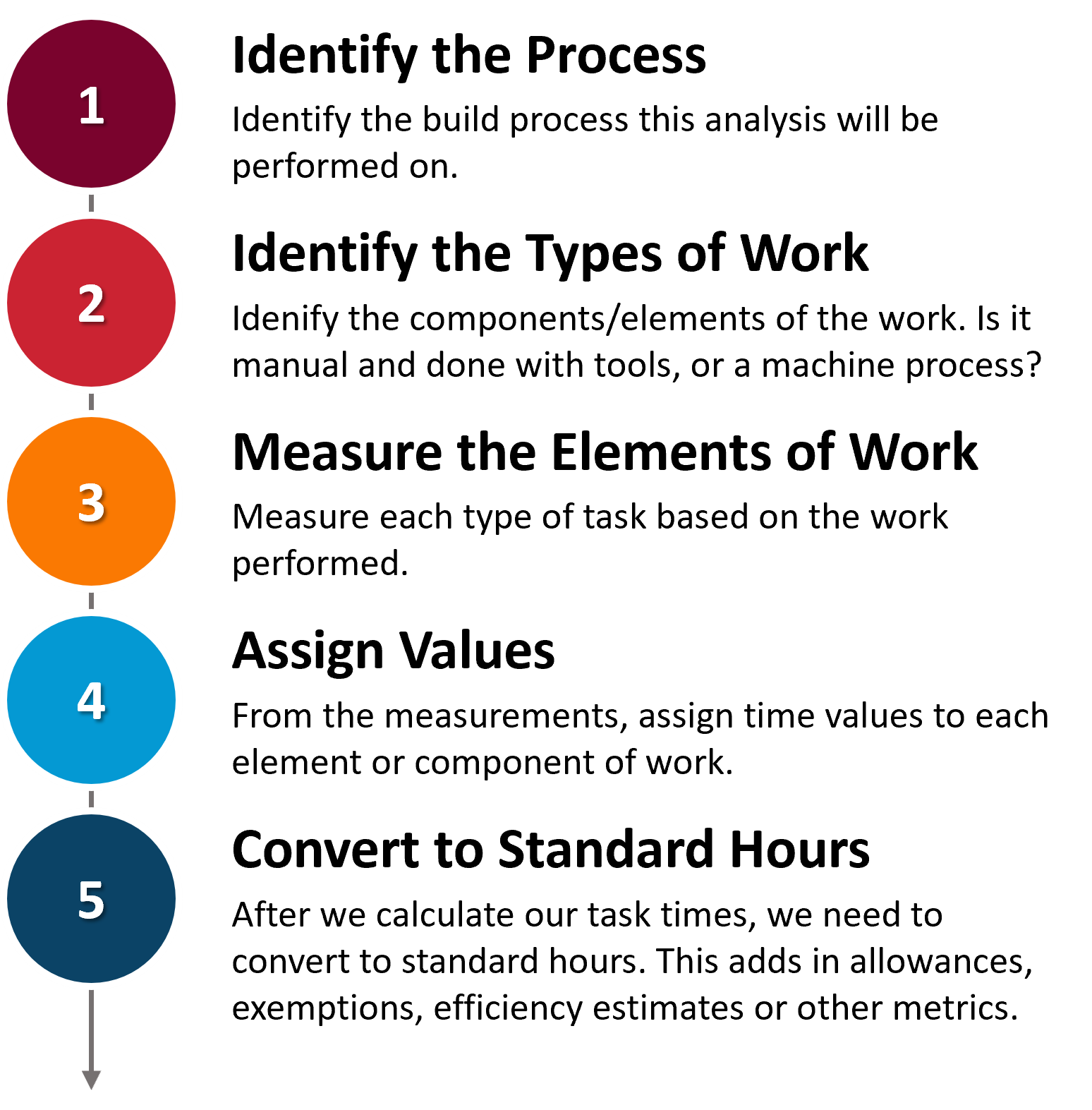

HOW TO PERFORM A PTMS / ENGINEERED TIME STUDY?

What are the Engineered Time Standards systems or methods?

Click Each Type Above to Learn More

LEARN ABOUT THE OTHER TIME STANDARD METHODS BELOW:

PRO vs CON

Overview of Benefits and Cons of Time Standard Type