Exploring Maynard Operation Sequence Technique (MOST): A Powerful Time Standard Method

In today’s fast-paced industrial landscape, optimizing operational efficiency is paramount for businesses striving to maintain a competitive edge. Among the various methodologies available, Maynard Operation Sequence Technique (MOST) stands out as a highly effective time standard method.

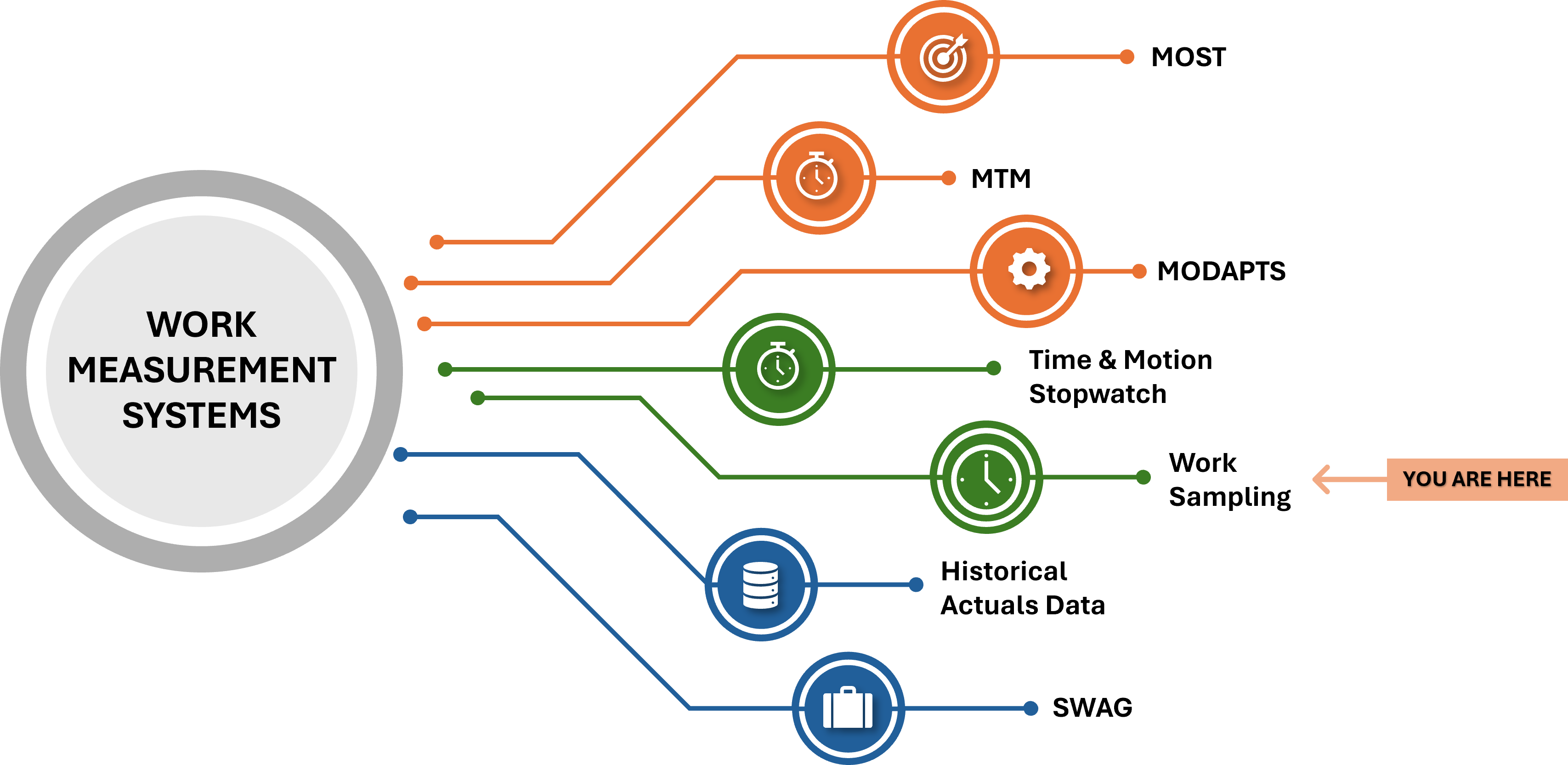

PMTS forms the foundation of MOST, providing a standardized framework for analyzing and estimating the time required to perform specific tasks. In this post, we’ll delve into the intricacies of MOST, its benefits, and its wide-ranging applications across industries.

Conclusion:

Maynard Operation Sequence Technique offers a systematic approach to optimizing work methods and establishing precise time standards across various industries. By leveraging MOST, organizations can drive efficiency, reduce waste, and ultimately achieve greater operational excellence in today’s competitive business landscape.

Leave a Reply