FACILITY DESIGN CONSULTANTING & INDUSTRIAL ENGINEERING CONSULTANTS

At Industrial-Engineered.com, we specialize in dynamic facility design consulting tailored to enhance your operational efficiency and support future growth. With decades of experience dating back to the 1990s, our industrial engineering consultants excel in creating bespoke solutions for a wide range of industries, including manufacturing, distribution, supply chain, and warehousing.

Comprehensive Facility Design Services

Our approach begins with a thorough assessment of your engineering, production, and operational needs. Unlike conventional firms, we prioritize cost effectiveness. This can include maximizing your existing space before considering expansions.

We understand that each business is unique. Our team of industrial and process engineers crafts solutions that align with lean six-sigma principles, ensuring minimal capital investment and reduced business risk. Whether you’re restructuring existing facilities or planning new expansions, our commitment remains steadfast: achieving your operational goals within budget.

FACILITY DESIGN PRINCIPALS

At the core of our approach lies the conviction that the quality of a facility design hinges on the principles and philosophy it embraces. Our practice is deeply rooted in lean manufacturing principles, which ensures:

Pull Based Systems

Ensuring material and product flows as needed, rather than pushing.

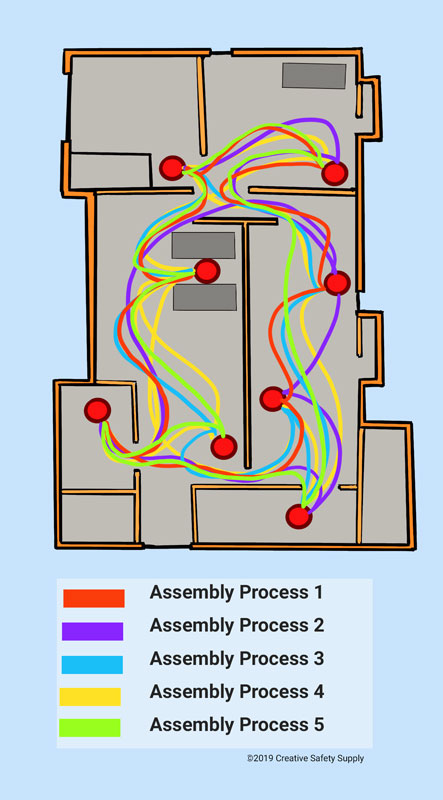

Waste Reduction

Reducing motion, transportation, wait times with factory flow.

Factory Organizing (5S Methodology)

Creating a set in order system for all items.

Continuous Flow

Analysis of product and material flow to ensure continuous and efficient factory flow.

Point of Use Storage

Storing and locating items where they will be used.

Operations Integration

Custom tailoring your build or business processes for max efficiency.

FACILITY DESIGN INPUTS

In contrast to many industrial design firms, our approach begins with a thorough assessment aimed at optimizing the use of current facilities before considering new constructions. We recognize that often, our clients’ needs involve enhancing the efficiency of their existing spaces rather than expanding them unnecessarily.

At Industrialengineer.co, our deep expertise in industrial and process engineering is complemented by a skilled team including process engineers, manufacturing operations specialists, and seasoned facility designers.

We believe that true success in facility design consulting is achieved only when our clients meet their operational objectives. These objectives encompass:

OUTPUTS AND DELIVERABLES

Our approach to facility design consulting is centered around comprehensively understanding your unique business requirements. Only by delving into these specifics can our industrial engineers develop customized solutions that precisely meet your needs. This tailored approach forms the bedrock for optimizing your manufacturing and distribution processes, seamlessly integrating people, equipment, technology, and facilities.

Our methodology prioritizes addressing operational needs before tackling facility issues, ensuring the development of site and facilities plans that:

DELIVERABLES

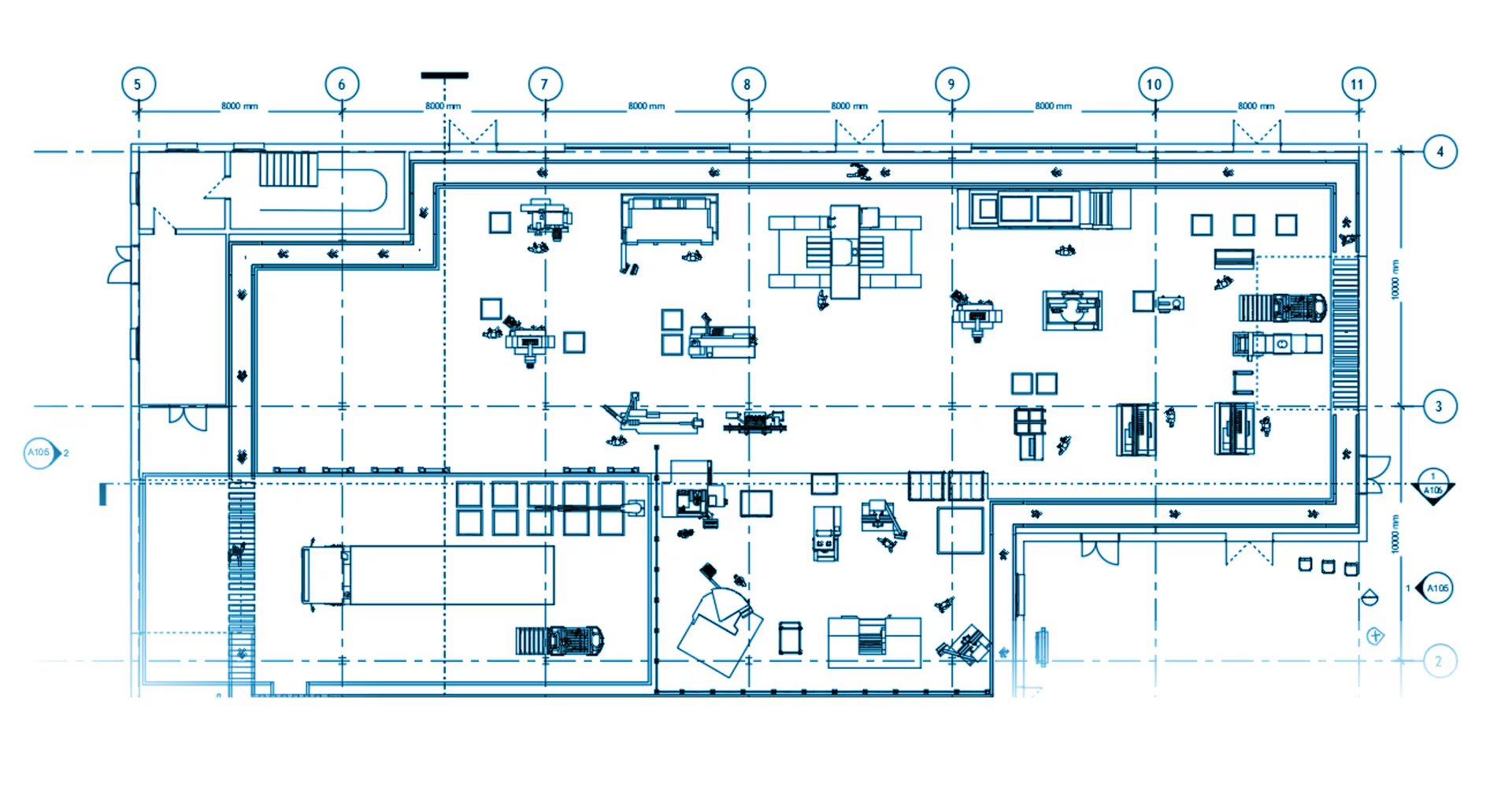

2D FACILITY LAYOUTS

3D FACILITY LAYOUTS

PRODUCT AND MATERIAL FLOW SERVICES

Choose Us for Your Facility Design and Industrial Engineering Needs

We specialize in creating efficient, effective, and scalable industrial facilities. Our expertise in facility design, plant layout, and capacity analysis ensures that your operations run smoothly and your business can grow without constraints.

COMPREHENSIVE FACILITY DESIGN

Space Utilization: Maximizing your available space to enhance productivity and safety.

Workflow Optimization: Designing layouts that streamline processes and reduce bottlenecks.

Flexibility and Scalability: Creating adaptable spaces that can evolve with your business needs.

Regulatory Compliance: Ensuring your facility meets all industry standards and regulations.

Continuous Improvement: Offering ongoing support to refine and optimize your plant layout as your operations evolve.

CAPACITY ANALYSIS FOR STRATEGIC GROWTH

Understanding and optimizing your capacity is essential for meeting demand and planning for future growth. Our capacity analysis services include:

Current Capacity Assessment: Evaluating your existing production capabilities and identifying constraints.

Future Demand Forecasting: Predicting future capacity needs based on market trends and business projections.

Capacity Planning: Developing strategies to enhance capacity through equipment upgrades, process improvements, and workforce optimization.

Risk Mitigation: Identifying potential bottlenecks and implementing contingency plans to ensure consistent production levels.

OUR PROCESS

We follow a systematic approach to deliver exceptional results for our clients:

1. Initial Consultation: Understanding your needs, challenges, and goals.

2. Data Collection: Gathering detailed information about your current operations, facilities, and workflows.

3. Analysis and Design: Using advanced tools and methodologies to analyze data and create optimized designs.

4. Implementation: Working closely with your team to implement the new designs and layouts effectively.

5. Monitoring and Support: Providing ongoing support to ensure sustained improvements and adapt to changing requirements.