WHAT IS LEAN?

Lean manufacturing is a systematic approach to eliminating waste and maximizing productivity in manufacturing processes.

WHY DO WE USE LEAN?

We use Lean to systematically identify and eliminate waste and optimize processes to their full potential.

The main goal is to ELIMINATE WASTE!

HOW IS IT USED?

In lean manufacturing, industrial engineers utilize tools like Value Stream Mapping (VSM) to visualize and analyze the entire production process and identify Waste in the Process.

Tools such as Kaizen events and 5S methodology are employed to systematically eliminate waste and standardize procedures, fostering a culture of continuous improvement.

By employing these tools and techniques, industrial engineers play a pivotal role in optimizing processes, enhancing quality, and increasing efficiency in manufacturing operations.

Click the Buttons Below to Learn More

BENEFITS OF LEAN

Reduced Waste: Industrial engineers analyze processes to identify and eliminate various forms of waste, such as overproduction, defects, and excess inventory, leading to streamlined operations and cost savings.

Increased Efficiency: performing time and motion studies to optimize workflows and layouts to minimize unnecessary movement and enhance productivity.

Empowered Workforce: fosters a culture of continuous improvement and employee involvement, empowering workers to identify problems, suggest solutions, and actively participate in process optimization.

Sustainable Practices: promotes sustainability by reducing waste, conserving resources, minimizing environmental impact, and supporting long-term business viability.

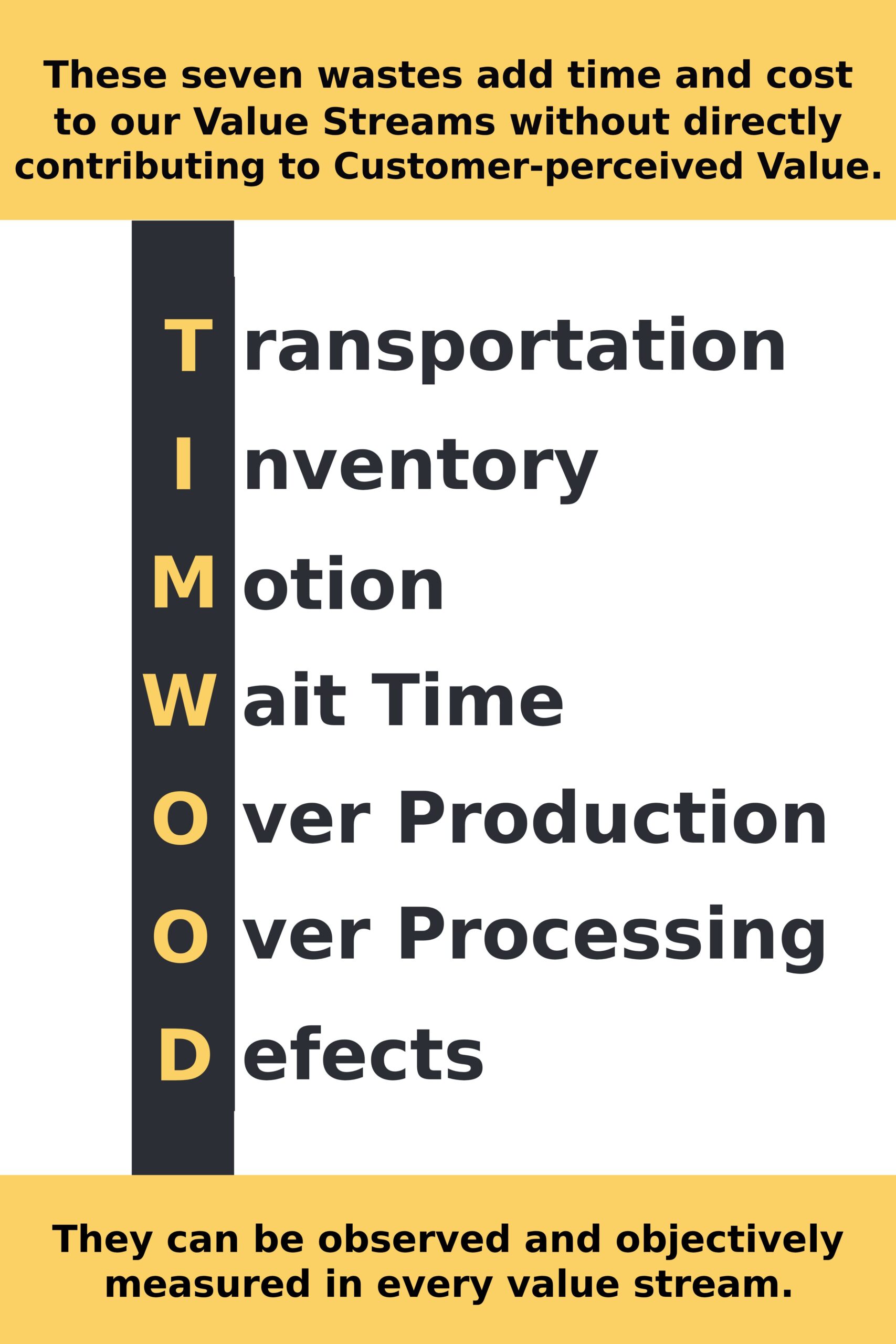

7 WASTES TO ELIMINATE

Optimize Your Operations with Lean & Industrial Engineering

We integrate Lean principles, Six Sigma methodologies, and advanced data analysis to drive excellence in industrial operations. Our goal is to help you achieve peak efficiency, reduce waste, and enhance quality across your processes. Discover how our expertise in Industrial Engineering can transform your business.

Lean Principles: Streamlining for Success

Lean methodology is at the core of our approach, focusing on eliminating waste and improving flow. Our services include:

Value Stream Mapping: Identifying and analyzing value-added and non-value-added activities to optimize processes.

Six Sigma: Achieving Quality Excellence

Six Sigma complements Lean by providing a structured approach to data-analysis and quality improvement. Our Six Sigma services include:

Lean Projects: Utilizing lean methodologies like DMAIC (Define, Measure, Analyze, Improve, Control) framework to tackle complex problems.

Process Capability Analysis: Assessing your processes to ensure they can consistently produce quality outcomes.

Root Cause Analysis: Identifying the underlying causes of defects and implementing long-term solutions.

Six Sigma Training: Certifying your employees as Green Belts, Black Belts, or Master Black Belts to lead quality initiatives.

Comprehensive Capacity Analysis

Understanding and optimizing your capacity is essential for meeting demand and planning for future growth. Our capacity analysis services include:

Current Capacity Assessment: Evaluating your existing production capabilities and identifying constraints.

Future Demand Forecasting: Predicting future capacity needs based on market trends and business projections.

Capacity Planning: Developing strategies to enhance capacity through equipment upgrades, process improvements, and workforce optimization.

Risk Mitigation: Identifying potential bottlenecks and implementing contingency plans to ensure consistent production levels.