DMAIC FRAMEWORK

DMAIC, a structured problem-solving methodology, aligns closely with lean principles by emphasizing data-driven decision-making and continuous improvement.

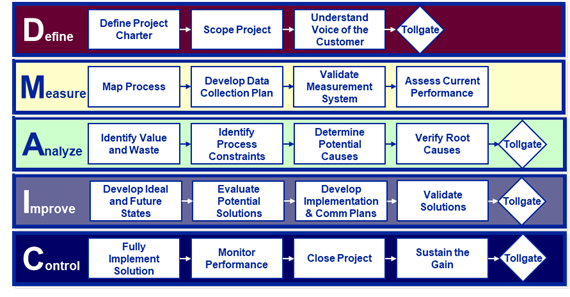

Through its Define, Measure, Analyze, Improve, and Control phases, DMAIC provides a systematic approach to identifying and eliminating waste, optimizing processes, and enhancing overall efficiency within lean manufacturing environments.

Click the Buttons Below to Learn More

FRAMEWORK OVERVIEW

FRAMEWORK BENEFITS

Structured Problem-Solving: provides a structured approach to problem-solving, ensuring systematic analysis and resolution of issues.

Data-Driven Decision Making: It emphasizes data collection and analysis, enabling informed decision-making based on objective evidence.

Continuous Improvement Culture: fosters a culture of continuous improvement by providing a framework for identifying and addressing process inefficiencies.

Reduced Variation: It aims to reduce process variation, leading to improved quality, consistency, and reliability of products or services.

Risk Reduction: By systematically analyzing processes and identifying root causes of issues, it helps in mitigating risks and preventing future problems.

Measurable Results: Through the use of performance metrics and key performance indicators (KPIs), it enables the measurement of improvement results, ensuring accountability and transparency.