WHAT IS A VALUE STREAM MAP?

Value Stream Maps (VSMs) are a detailed variant of process maps and are a method to categorizing process value. Typically, we start with a process map event and then transition towards identifying Value-Added or Non-Value-Added steps, along with the 7 Wastes.

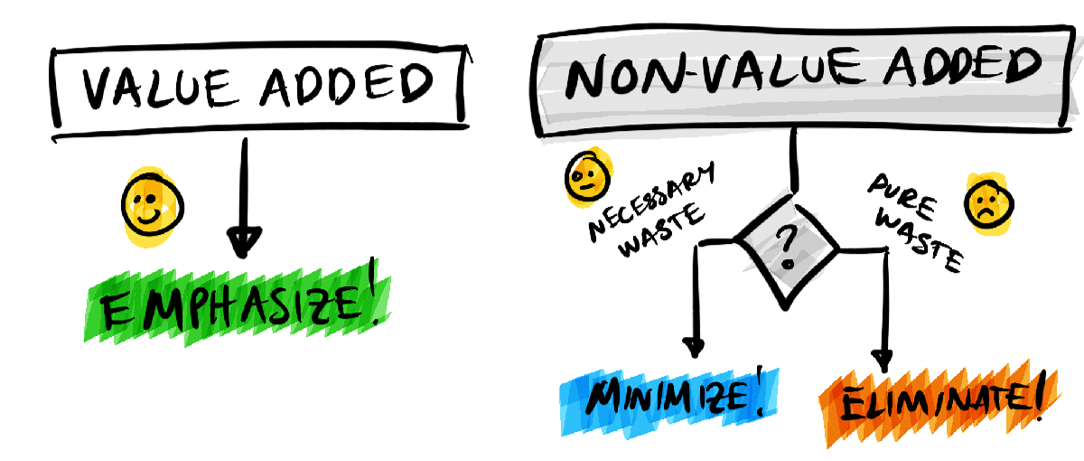

VALUE-ADDED (VA) / NON-VALUE ADDED (NVA)

Value-Added Activities directly contribute to customer value/needs, while Non-Value Added often represent the 7 Wastes. Identifying and eliminating Non-Value Added Activities helps streamline processes and reduce these wastes.

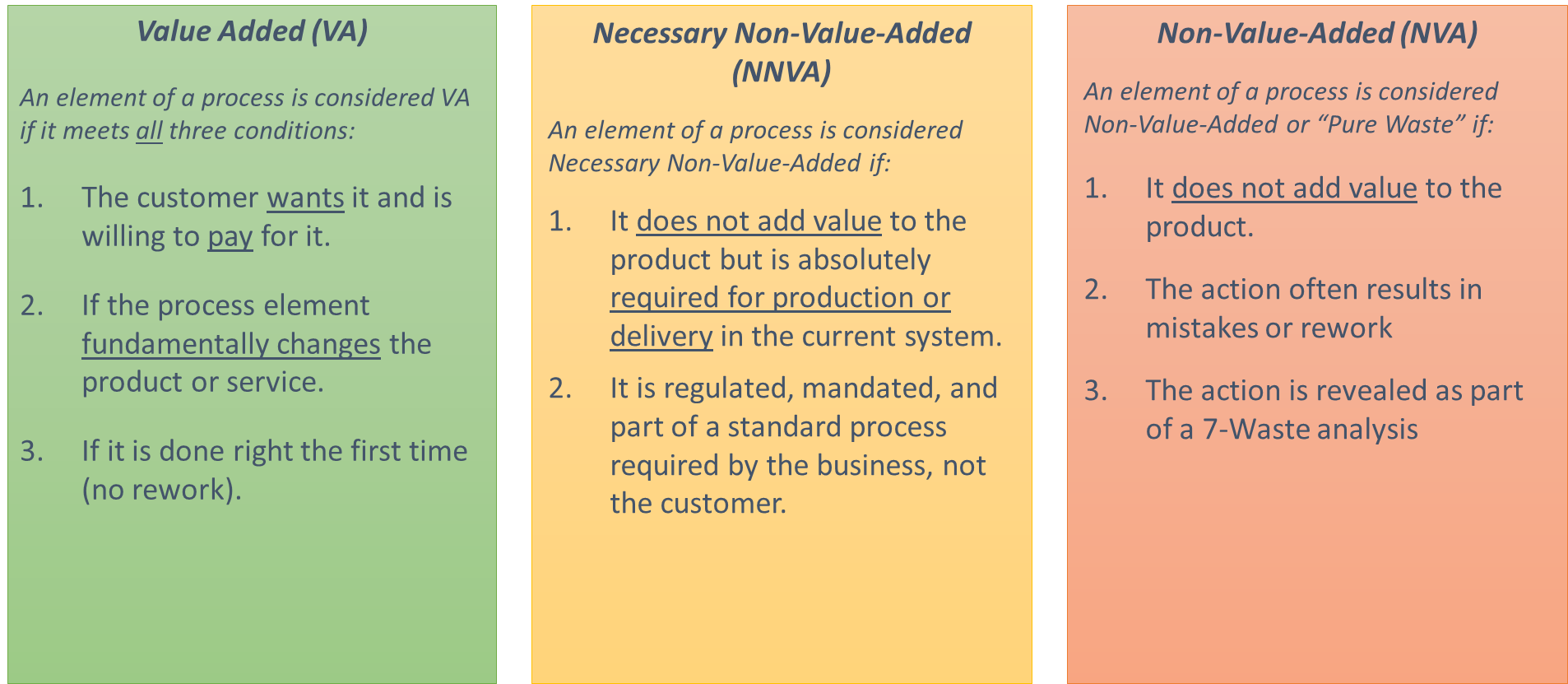

TYPES OF VALUE

VALUE ADDED

Change the fit, form, or function of the item being worked, it is done right the first time, and the internal/external customer is willing to pay for it.

NON-VALUE ADDED (NECESSARY)

Some NVA activities are required and must be done (Regulatory, Safety, Legal, etc.).

Example: The Customer requires a final inspection to be performed before shipping.

NON-VALUE ADDED

Consume time / resources but do not directly add to the value of the product.

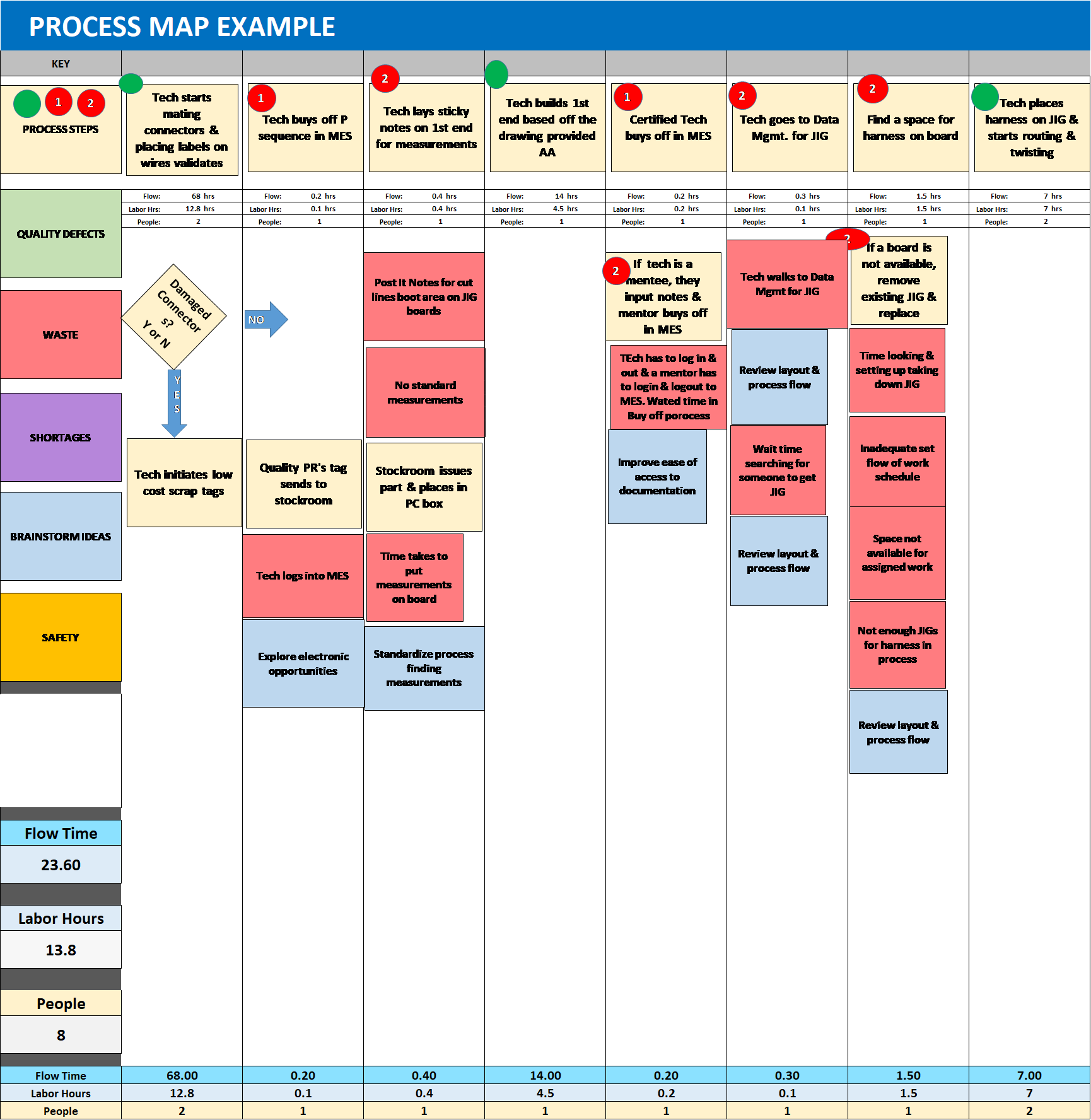

HOW TO PERFORM A VALUE STREAM MAP?

1. IDENTIFY YOUR PROCESS

First things first, let’s pick a process to map out. It could be something as simple as making your morning coffee or as complex as revamping the entire customer support system at work. Choose wisely, my friend.

2. FORM YOUR TEAM (OPTIONAL)

If you’re working on a process that involves multiple people or departments, it might be a good idea to gather the troops for this mapping adventure. More brains means more perspectives, and that’s always a good thing.

3. START MAPPING

Start Mapping Grab a piece of paper, a whiteboard, or your favorite digital mapping tool – whatever floats your boat. Now, begin by jotting down the first step of your process. Let’s say it’s “Gather ingredients” for our morning coffee example.

4. CONNECT THE DOTS

Connect the Dots Once you’ve got your first step down, it’s time to add the next one. Think about what comes next logically in the process. Maybe it’s “Grind coffee beans” or “Boil water.” Draw a line connecting each step to show the flow from one to the next.

IDENTIFT VA AND NVA STEPS

After the rough process map is laid out, we need to go through each step to identify the type of Value-Add or Non-Value-Add associated. Typically, the Non-Value-Added steps we look to outright eliminate from the process.

5. ANALYZE WASTES AND IMPROVEMENTS

Once your map is complete, go step by step to identify the different Wastes in the Process. Mark the Wastes with a Red Note and a corresponding Improvement idea with a Blue Note.