Let’s Map It Out: A Beginner’s Guide to Creating a Process Map!

Hey there, fellow explorer of efficiency! Ever found yourself tangled in the web of confusion when trying to understand a complex process?

Today, we’re diving headfirst into the world of process mapping, and I’ll be your trusty guide through this adventure.

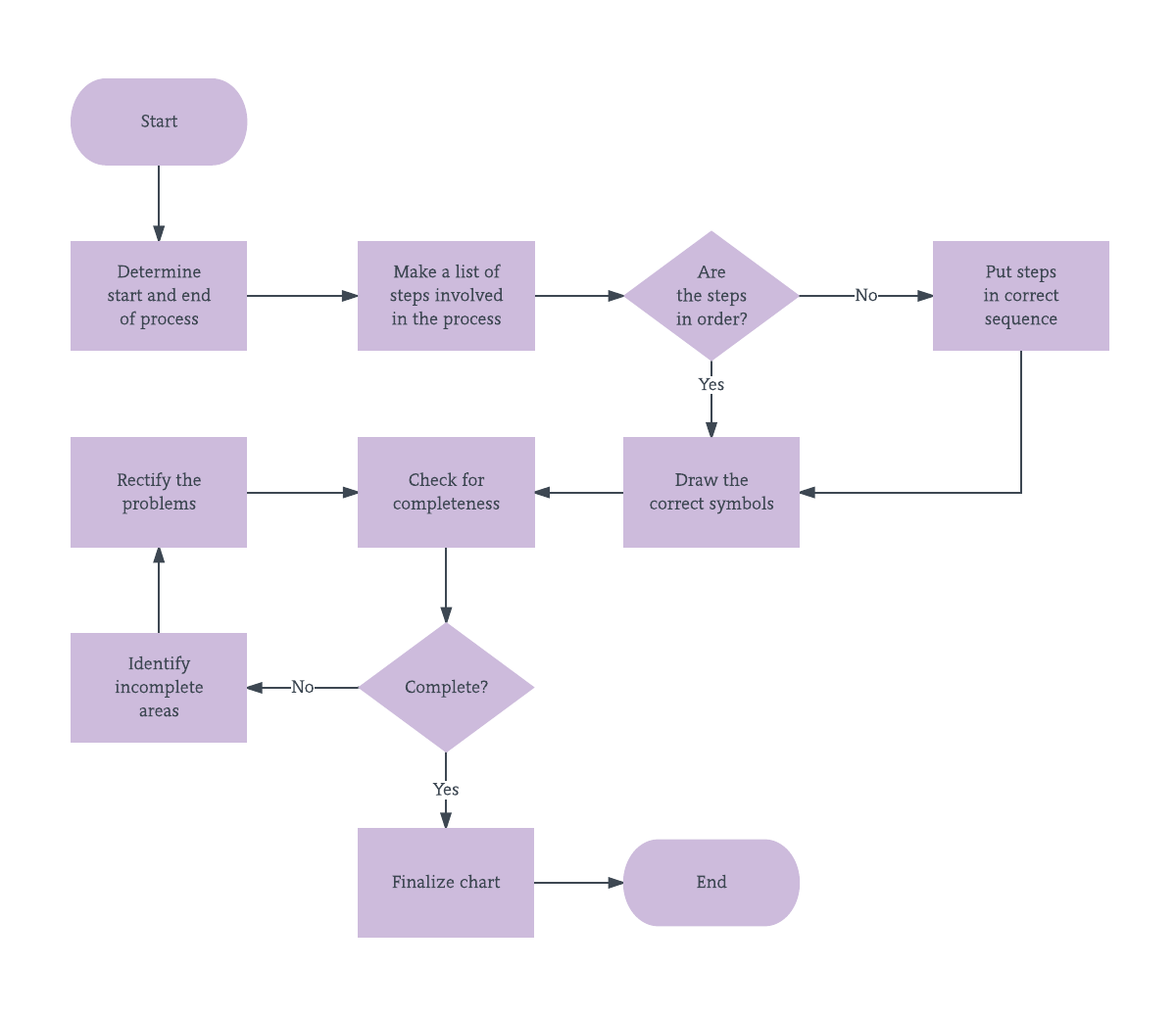

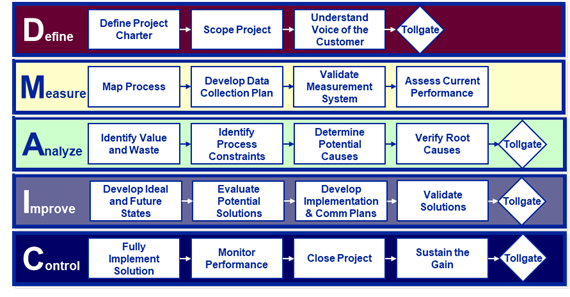

So, what exactly is a process map? Well, think of it as a treasure map, but instead of leading you to buried gold, it guides you through a series of steps in a process.

Whether it’s making a sandwich or launching a rocket into space, every process has its own map, and we’re about to draw one.

1. IDENTIFY YOUR PROCESS

First things first, let’s pick a process to map out. It could be something as simple as making your morning coffee or as complex as revamping the entire customer support system at work. Choose wisely, my friend.

2. FORM YOUR TEAM (OPTIONAL)

If you’re working on a process that involves multiple people or departments, it might be a good idea to gather the troops for this mapping adventure. More brains means more perspectives, and that’s always a good thing.

3. START MAPPING

Start Mapping Grab a piece of paper, a whiteboard, or your favorite digital mapping tool – whatever floats your boat. Now, begin by jotting down the first step of your process. Let’s say it’s “Gather ingredients” for our morning coffee example.

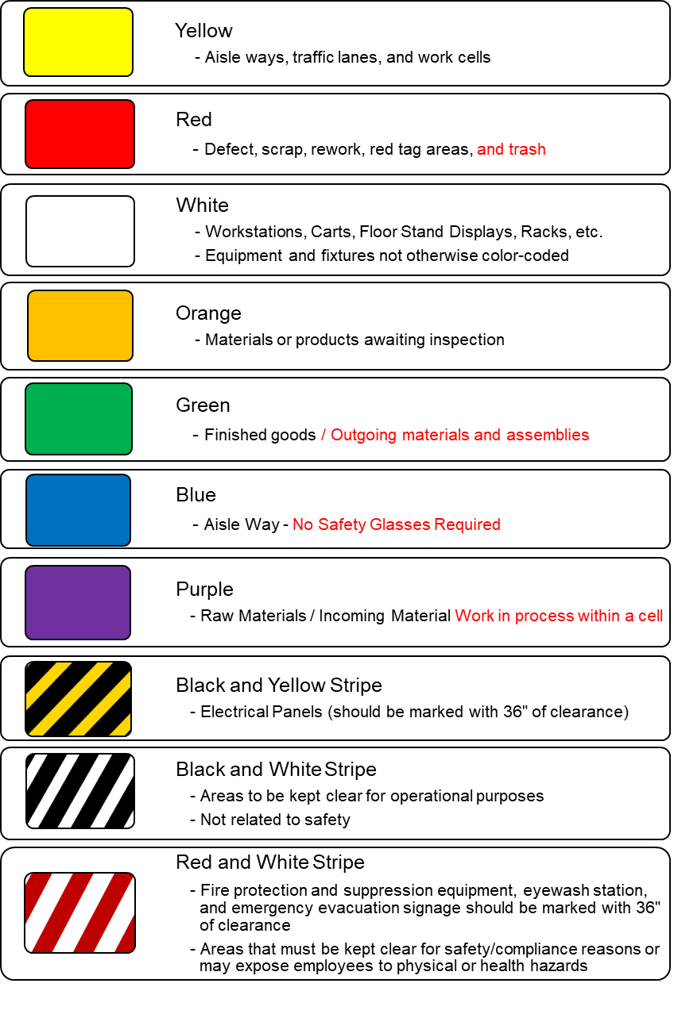

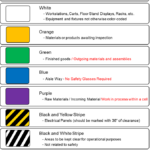

Make sure to mark each step in accordance with it’s corresponding Process Symbol!

4. CONNECT THE DOTS

Connect the Dots Once you’ve got your first step down, it’s time to add the next one. Think about what comes next logically in the process. Maybe it’s “Grind coffee beans” or “Boil water.” Draw a line connecting each step to show the flow from one to the next.

Make sure to mark each step in accordance with it’s corresponding Process Symbol!

5. FILL IN THE DETAILS

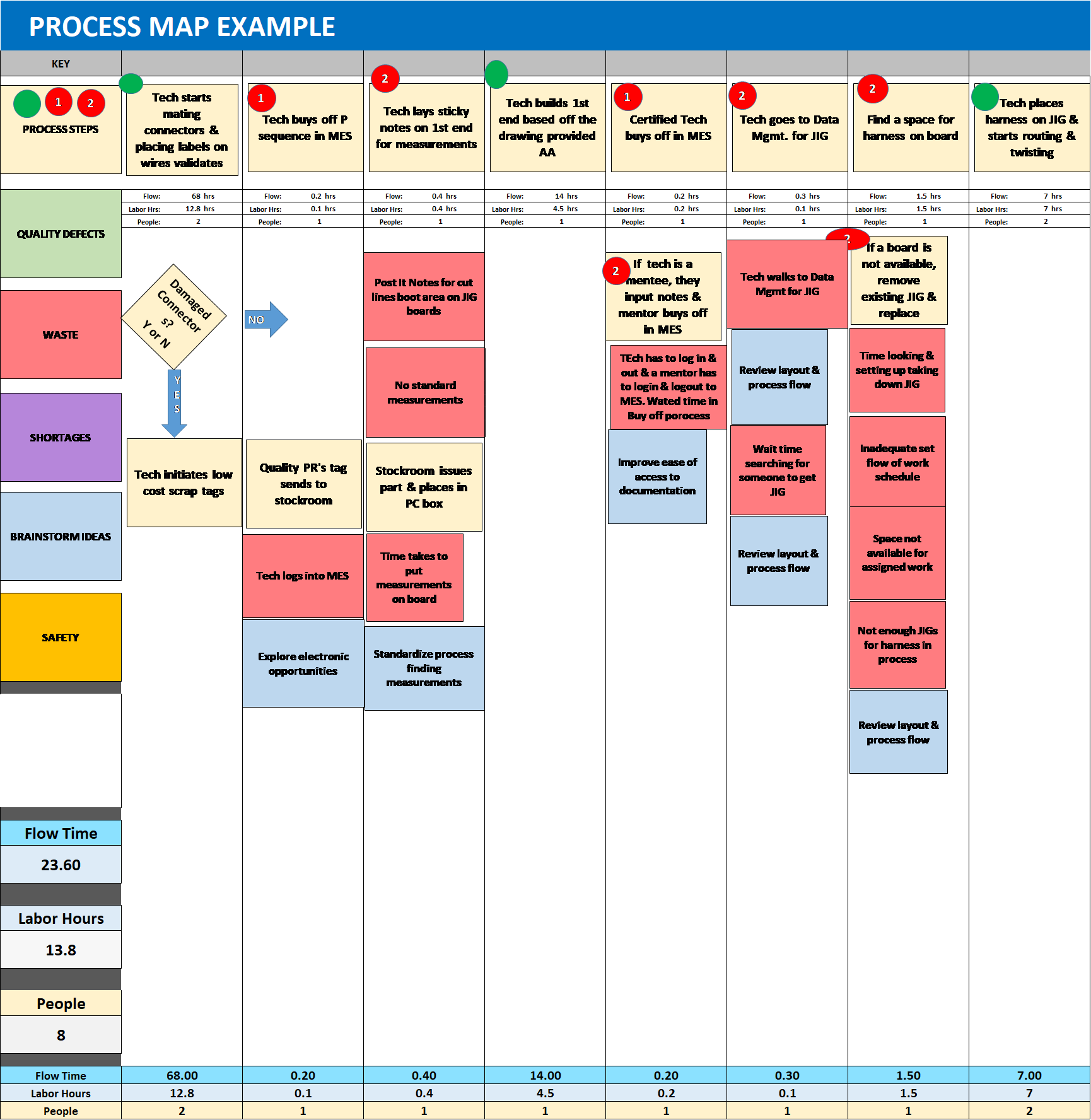

This is a very IMPORTANT waste identification step. As you add more steps to your map, don’t forget to include important details like who is responsible for each step, any tools or resources needed, and any decision points along the way. The devil is in the details, as they say!

Conclusion:

A finished process map/value stream map should contain a map or flow of the process, along with identified wastes, opportunities, cycle times, and number of people involved and should easily illustrate a flow of general process.

Looking for more in-depth Guides? Check out Learn Lean Sigma.

Leave a Reply