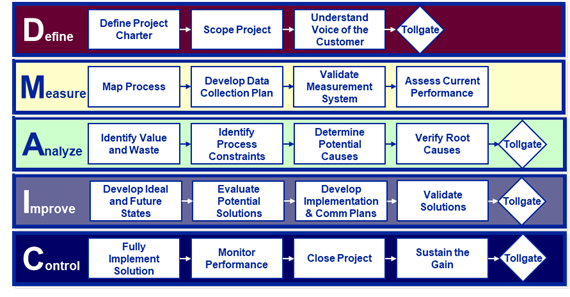

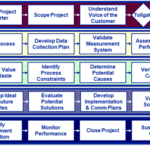

Conclusion:

Understanding these symbols empowers teams to create, interpret, and improve process maps effectively. By visually depicting workflows and clarifying responsibilities, process maps become invaluable assets in driving efficiency, identifying bottlenecks, and fostering continuous improvement.

Leave a Reply