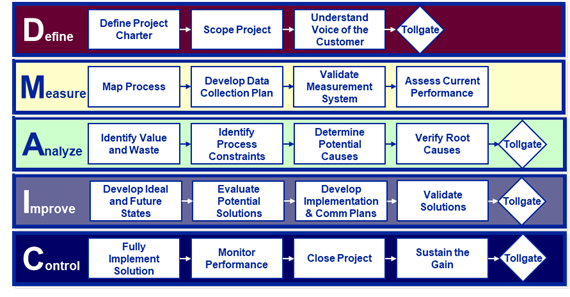

1. Layout and Flow Optimization:

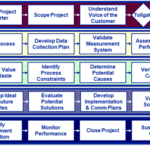

Efficient movement of materials, personnel, and products is the cornerstone of a well-designed manufacturing facility. Utilizing principles such as Lean Manufacturing and Six Sigma, layout design should minimize waste, reduce bottlenecks, and optimize workflow. This involves strategic placement of equipment, assembly lines, and storage areas to ensure seamless operations from raw materials to finished goods.

2. Flexibility and Adaptability:

In today’s dynamic market, the ability to adapt quickly to changing demands is crucial for success. Designing flexible manufacturing spaces allows for easy reconfiguration of production lines, accommodating new products or process changes without significant downtime. Modular designs and scalable infrastructure enable manufacturers to stay agile and responsive to market fluctuations.

3. Integration of Technology:

Embracing automation, robotics, and digitalization revolutionizes manufacturing processes, enhancing efficiency, precision, and quality. Incorporating state-of-the-art technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and data analytics optimizes production scheduling, predictive maintenance, and quality control. Smart manufacturing facilities leverage real-time data to make informed decisions and continuously improve performance.

4. Sustainability and Environmental Responsibility:

With increasing awareness of environmental issues, sustainable practices have become imperative for manufacturing facilities. Designing for energy efficiency, waste reduction, and resource conservation not only minimizes ecological impact but also lowers operational costs and enhances brand reputation. Implementing renewable energy sources, eco-friendly materials, and efficient waste management systems aligns with sustainable development goals.

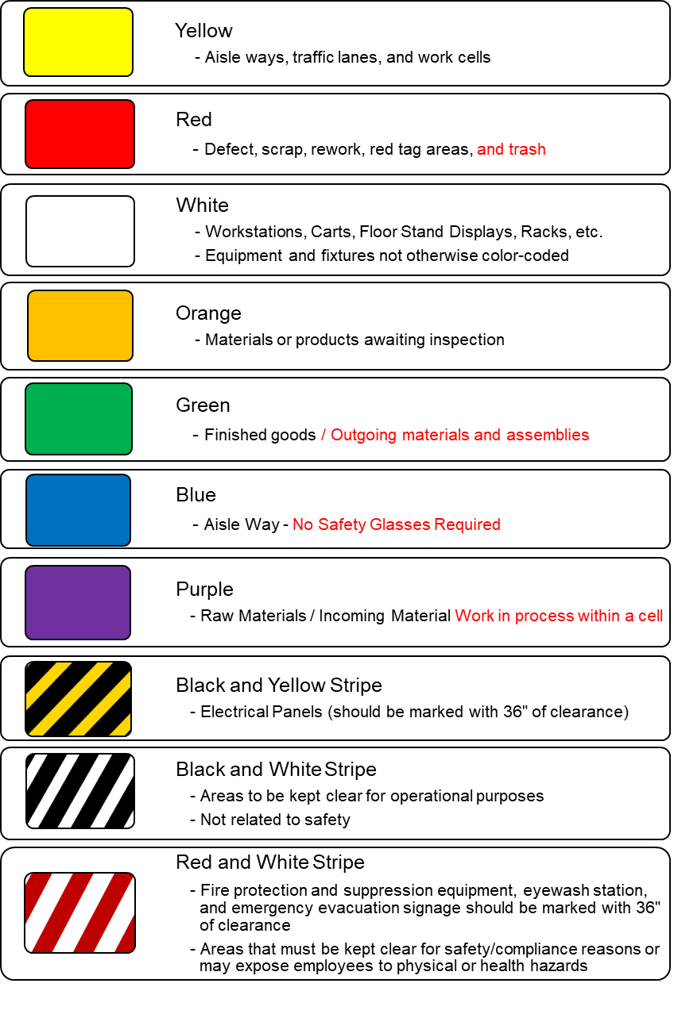

5. Safety and Ergonomics:

Prioritizing worker safety and comfort is essential for maintaining a productive and motivated workforce. Designing ergonomic workstations, implementing safety protocols, and incorporating automated safety systems minimize accidents and injuries. Factors such as lighting, ventilation, and noise control also contribute to a safe and conducive working environment, promoting employee well-being and productivity.

6. Collaboration and Innovation Spaces:

Encouraging collaboration and fostering a culture of innovation are vital for staying ahead in today’s competitive market. Designing collaborative spaces, such as brainstorming rooms, innovation labs, and cross-functional work areas, promotes knowledge sharing, creativity, and problem-solving. By bringing together diverse teams and expertise, manufacturing facilities can drive continuous improvement and technological advancement.

Conclusion:

Innovation in manufacturing facility design goes beyond aesthetics; it’s about creating environments that empower organizations to thrive in a rapidly changing world. By optimizing layout, embracing technology, prioritizing sustainability, ensuring safety, and fostering collaboration, manufacturers can build facilities that not only meet current needs but also anticipate and adapt to future challenges. As the manufacturing landscape continues to evolve, strategic facility design will remain a cornerstone of success.

Marcus Rosati

B.S. Industrial Engineering – Purdue UniversityB.S. Industrial Management – Purdue University

Lead Industrial Engineer for Process Improvement Projects

Revolutionizing Metal Deburring with Chemical Deburring: Automate Manual Deburring

Introduction In the realm of precision engineering, achieving flawless surfaces on metal parts is crucial…

Tackling the Challenges of Medium and High Volume Manufacturing: Effective Mitigation Strategies

Introduction Medium to high volume manufacturing is characterized by the production of large quantities of…

Top 4 Manufacturing Facility Design Consulting and Plant Layout Consultants

Introduction In the fast-paced world of manufacturing, efficiency is not just a goal but a…

Production Planning in Manufacturing: Tools and Programs for Enhanced Efficiency

Introduction to Production Planning In the dynamic world of manufacturing, optimizing production schedules is crucial…

Essential Guide for Deburr Methods in Modern Manufacturing

Introduction to Deburr Methods in Manufacturing In the world of manufacturing, precision and quality are…

Facility Design in Manufacturing Plants: Work Cells, Machinery, and Tooling

Introduction to Facility Design and Planning Facility Design is a critical aspect of manufacturing plant…

Leave a Reply