SHINE 5S

During the Shine phase of 5S, workspaces are thoroughly cleaned and maintained to uphold standards of cleanliness and safety. Tasks in this phase include removing dirt, dust, and debris from surfaces, inspecting equipment for defects or abnormalities, and establishing regular cleaning schedules.

By fostering a clean and organized environment, the Shine phase aims to prevent accidents, improve morale, and prolong the lifespan of equipment.

SHINE GUIDELINES

Along with cleaning and maintenance, this phase should also include inspection and routing maintenance.

As teams perform daily cleaning routines, they should also make an effort to inspect tools and machinery for damages. Periodic maintenance should be performed in this phase as well.

SHINE STRATEGIES

Regular Cleaning

-Establish shift changeover procedures

-Establish cleaning frequency and checklist

– Train on best practices and procedures

Preventative Maintenance

– Spare Parts Lists

– Spare Parts Inventory

– Maintenance schedules and checklists

Checklists and Procedures

Checklists help drive the sustainment of the tasks. This is crucial for establishing regular frequency of cleanings and have a set process for cleaning between shifts.

PHASES

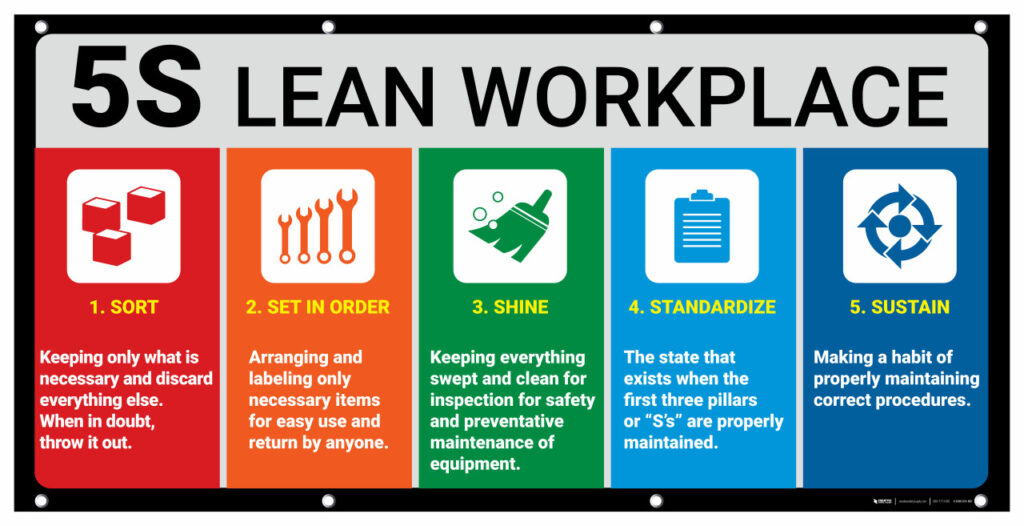

Click each Step below to learn more about the 5S Process.