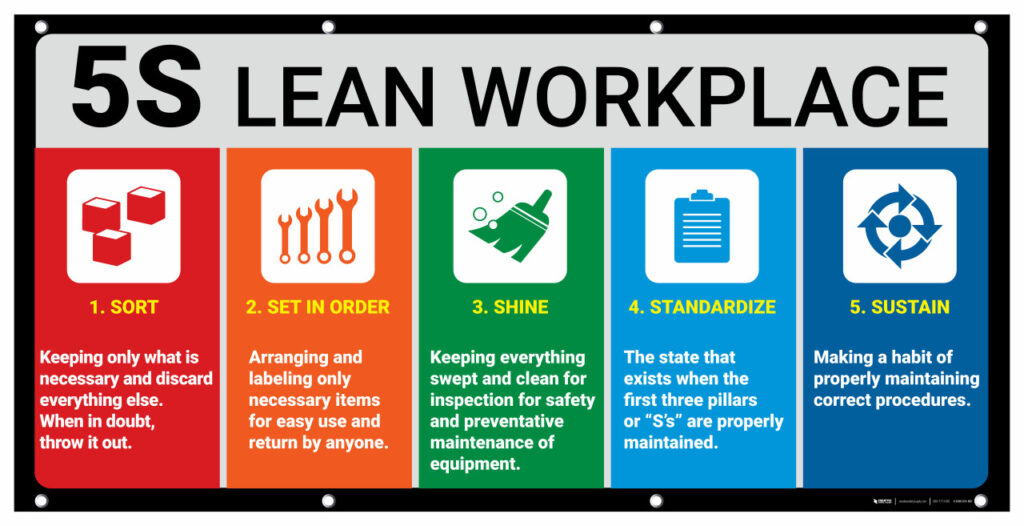

STANDARDIZE 5S

In the Standardize phase of 5S, procedures and guidelines are established to maintain the improvements made in the previous phases. Tasks include documenting cleaning schedules, creating visual aids such as checklists and standard operating procedures, and training employees on the standardized processes.

This phase ensures consistency across operations, promotes accountability, and facilitates continuous improvement efforts within the organization.

STANDARDIZE GUIDELINES

– Make sure responsibilities are clear and understood well

– Implement Standardization into the daily routine

– Periodic evaluation of prior 5S tasks

STANDARDIZE STRATEGIES

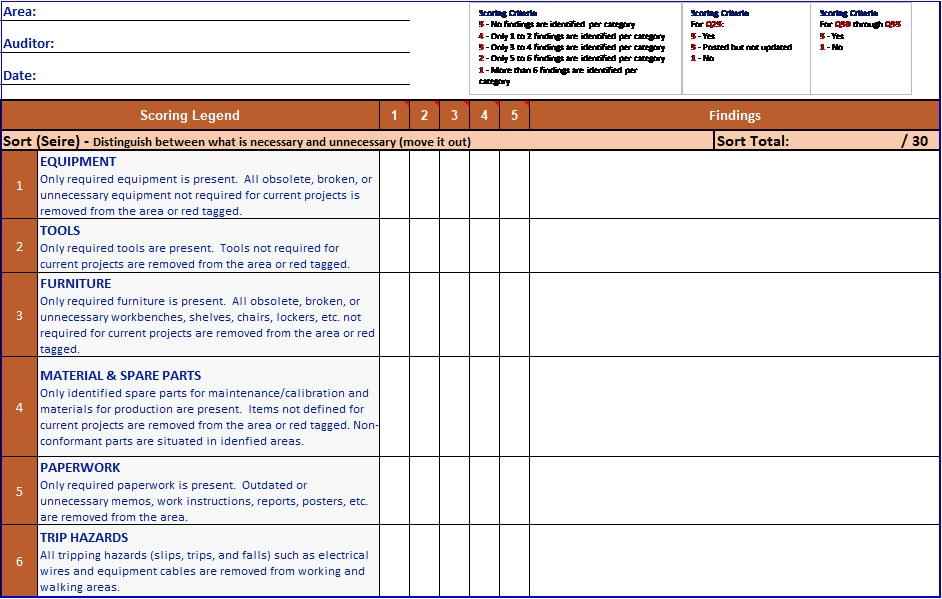

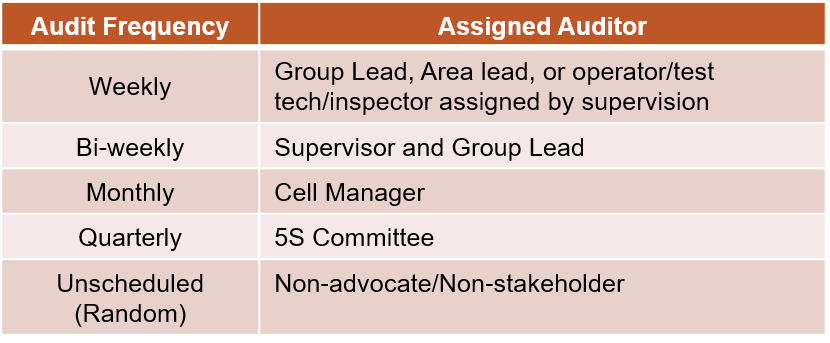

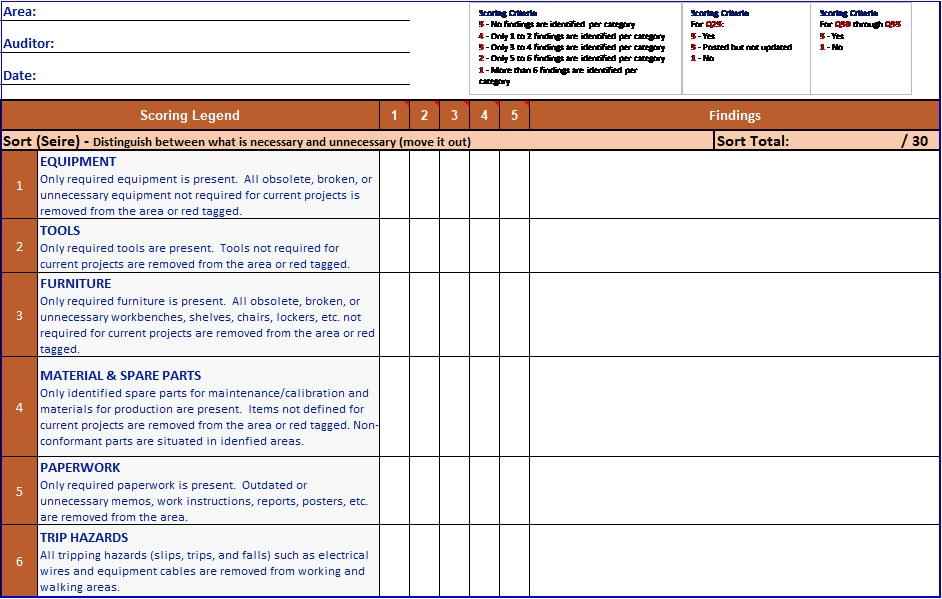

PERIODIC EVALUATION

Periodic evaluation is crucial for maintenance of the standardization of 5S. This ensures that all 5S efforts are following a standardized process and there is site-wide oversight for this process.

STANDARD CHECKLISTS

Creating standard checklists and task lists

SUPERVISION / MANAGEMENT

5S Buy-In needs to occur at all levels throughout the organization. While the workers are the one’s maintaining, supervision and management needs to allocate time and budget for these tasks to be performed. It’s important that supervision and management also are Subject Matter Experts (SMEs) in the 5S Process.

PHASES

Click each Step below to learn more about the 5S Process.