DIRECT OBSERVATION INTRODUCTION

Welcome to our exploration of direct observation time standards in manufacturing.

Here, we delve into the essential principles of optimizing workflows through precise observation techniques. Learn how to set accurate time standards, improve efficiency, and enhance productivity in your workplace. Dive into actionable insights and practical strategies to streamline operations and achieve peak performance.

When do we use Direct Observation as a method for our Time Standard?

Limited Data and Limited Engineer Resources, less time consuming than engineered time standards, but not as simple as Time Estimates.

Complex or Variable Tasks, ideal when tasks involve intricate steps or vary in complexity, as they allow for a visual analysis of each component in real-time.

Training and Skill Development enables trainers to closely monitor trainees, provide immediate feedback, and tailor instruction to individual learning needs, fostering skill development effectively.

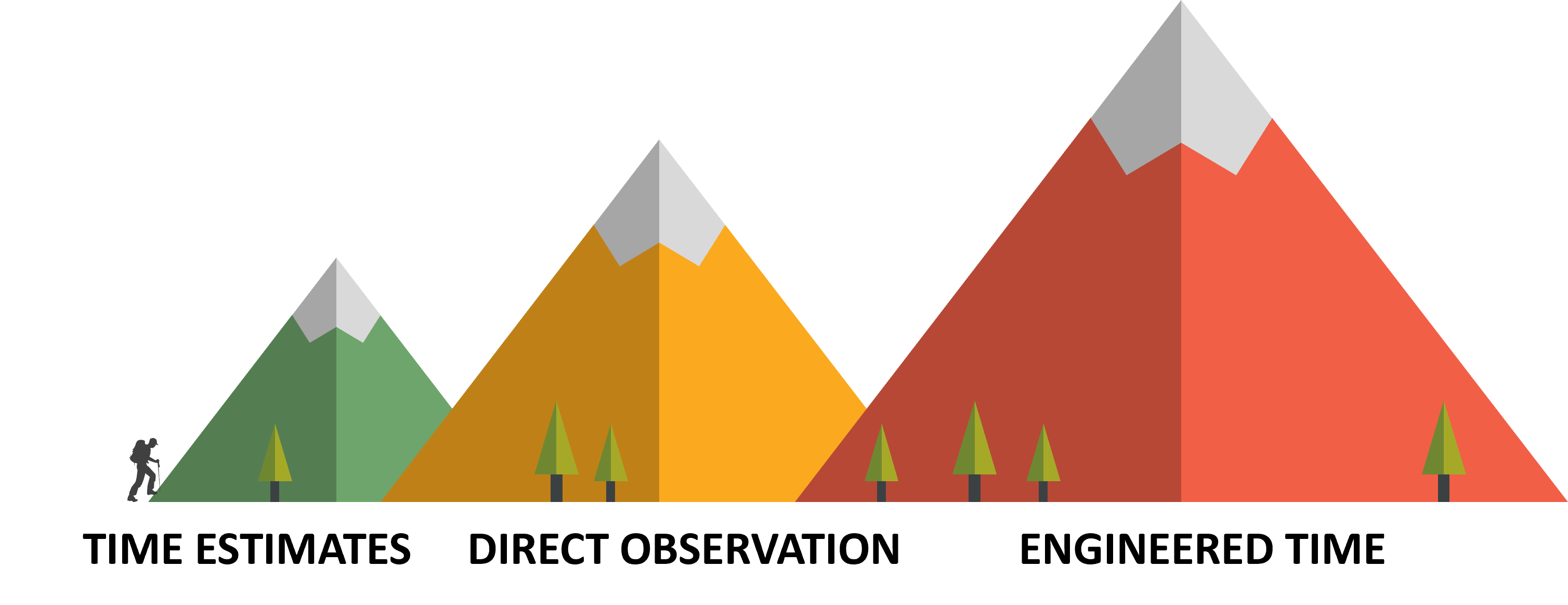

Effort of Implementation

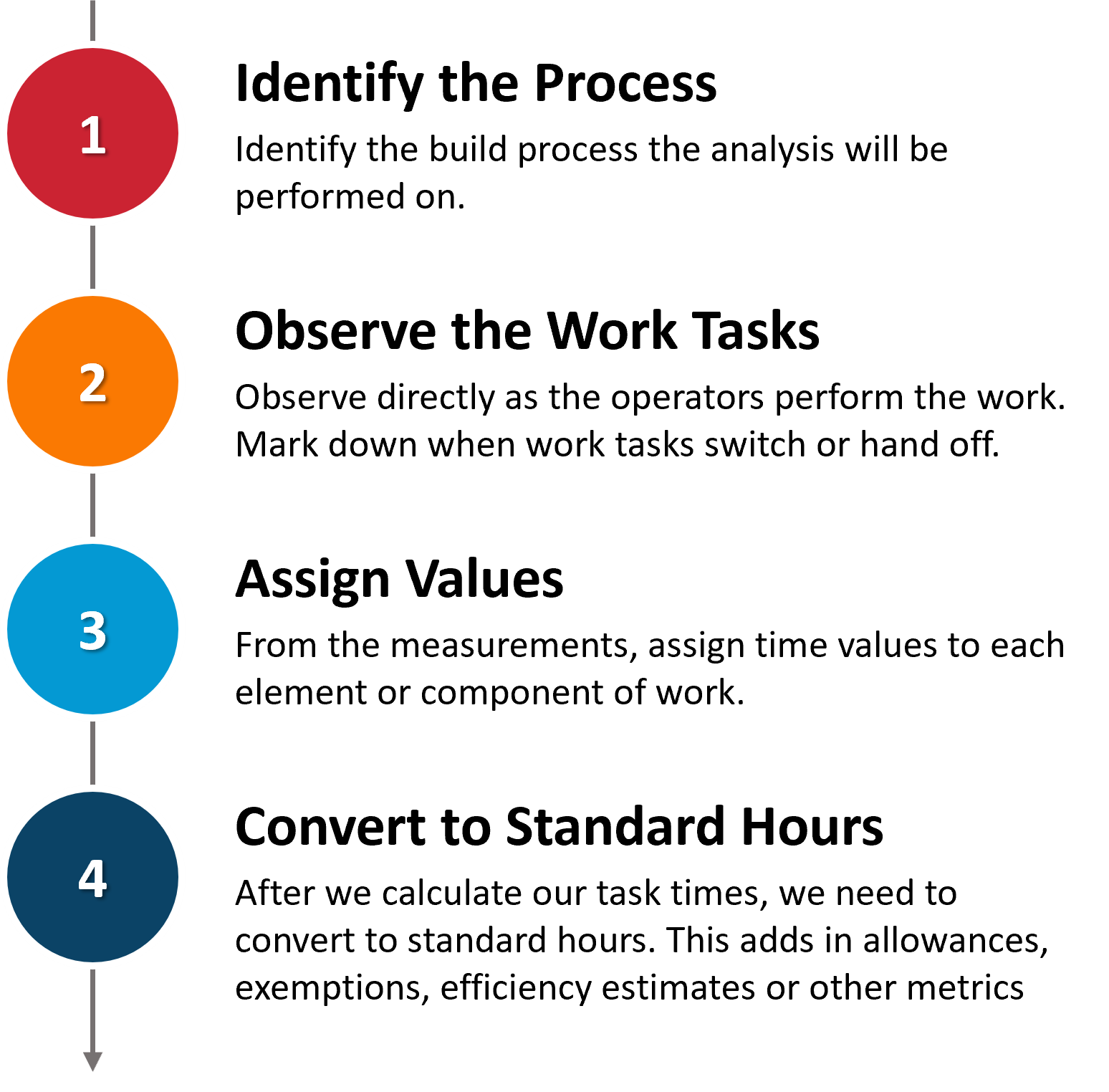

HOW TO PERFORM A DIRECT OBSERVATION TIME STUDY?

What are the Direct Observation systems or methods?

Click Each Type Above to Learn More

LEARN ABOUT THE OTHER TIME STANDARD METHODS BELOW:

PRO vs CON

Overview of Benefits and Cons of Time Standard Type