MOTION & STOPWATCH INTRODUCTION

Welcome to our exploration of stopwatch time studies, a method of Direct Observation Time Standards.

Discover the backbone of efficient workflow management with our exploration of motion and stopwatch time standard methods. In industries ranging from manufacturing to service, precise time measurements are crucial for optimizing processes. Whether you’re a seasoned professional or new to the concept, unlock the potential of motion and stopwatch time standards with our expert guidance.

When do we use Stopwatch Study as a method for our Time Standard?

Hidden Waste Identification, allow for accurate recording of the time taken to complete individual tasks and captures hidden work not called out in documentation.

Standardizing Work, these studies allow for best practices analysis and work standardization to be performed.

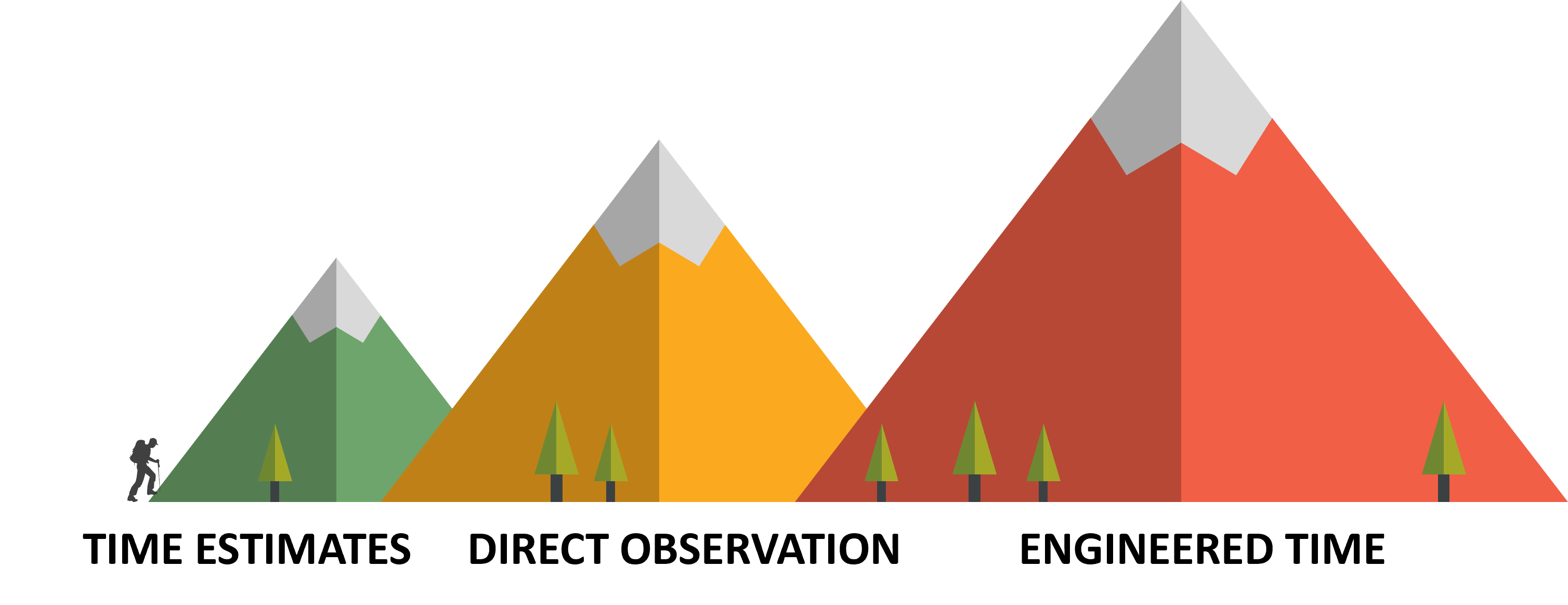

Low Training Barrier, provides similar accuracy to Engineered Standards with low training and resources required.

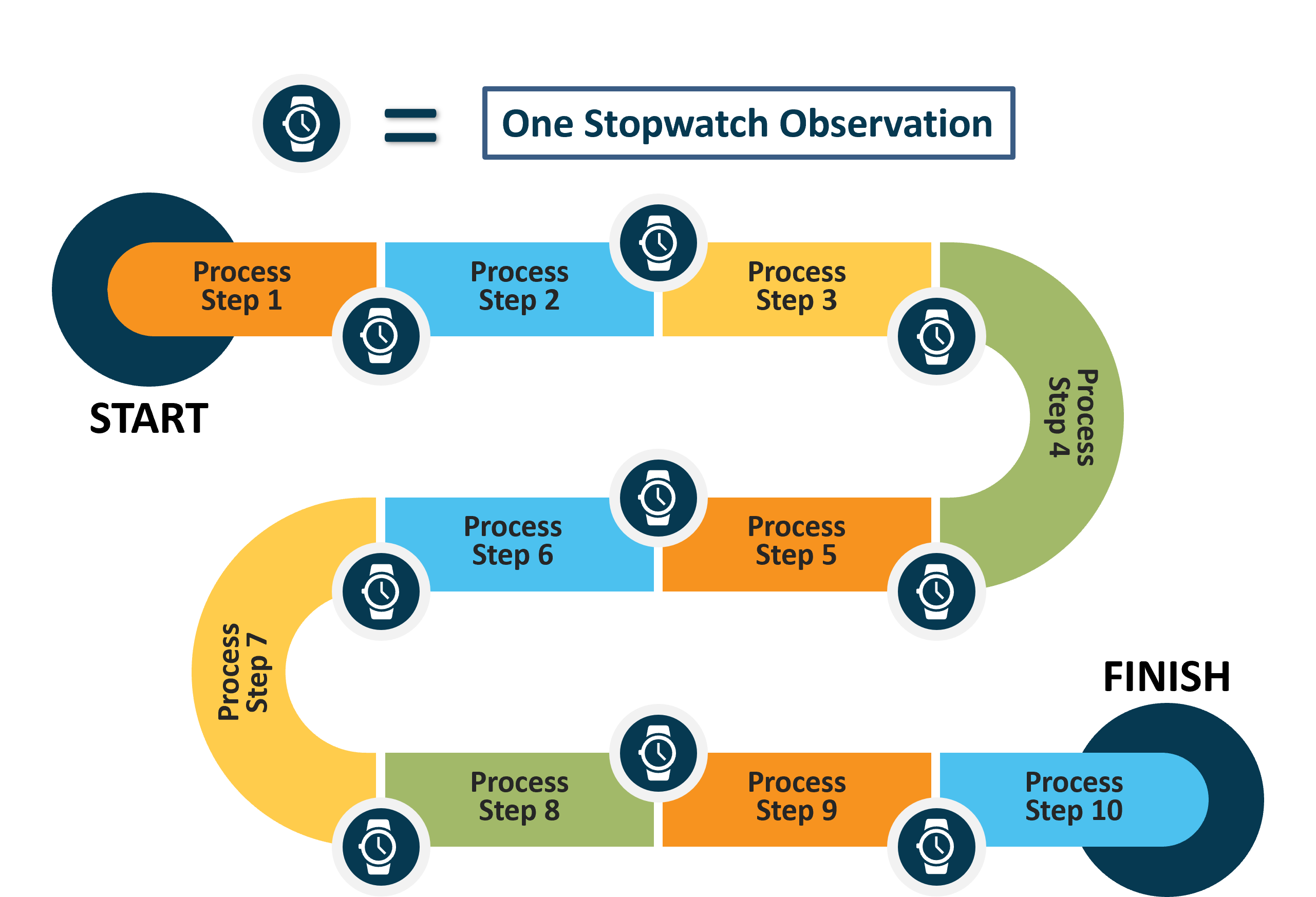

HOW TO PERFORM A STOPWATCH TIME STUDY?

At the conclusion of each process step, a stopwatch recording is made to note the Total Process Time.

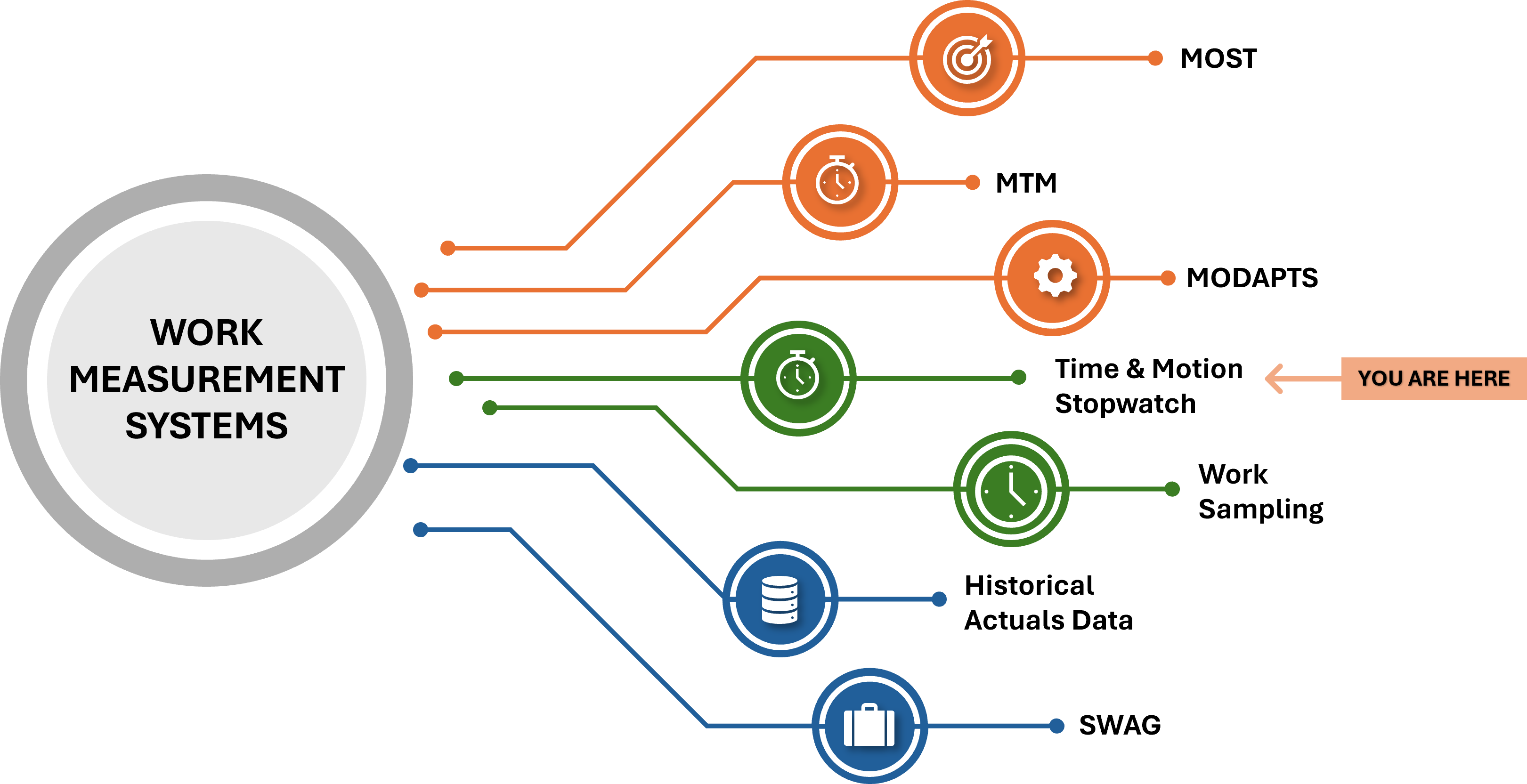

LEARN ABOUT THE OTHER TIME STANDARD METHODS BELOW:

PRO vs CON

Overview of Benefits and Cons of Time Standard Type